Georgia Code

GA 2020 Energy Code Overview Background

As of January 1, 2020, Georgia’s new energy code is the 2015 IECC + 2020 GA Supplements and Amendments, which supersedes the 2009 IECC (with 2011 GA Supplements and Amendments).

Changes and Highlights

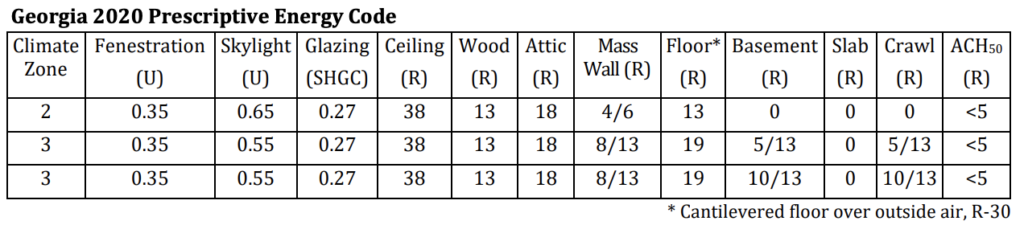

Georgia’s 2020 energy code brings forward several current amendments and introduces a few new ones. It includes enhanced graphics in Appendix RA that illustrate proper construction details for insulation installation as well as envelope and duct sealing. The amended code brings minimal changes to the building thermal envelope components: – Ceiling insulation increases from R-30 to R-38 in CZ2 and CZ3 but remains R-38 in CZ4. – Windows get better (in theory) but effectively remain the same windows that are commonly being installed today (max. U-factor = 0.35, max. SHGC = 0.27). – Single-family house leakage drops to < 5 ACH50 (an improvement from the previous < 7 ACH50 but not as stringent as the < 3 ACH50 IECC target).

For ducted mechanical systems, duct leakage improves from 12% to 6% for Total Leakage at Final, but remains at 6% for Total Leakage at Rough-In. Additionally: – Duct leakage-to-outside is no longer recognized as a testing option. – New home heat pump systems require supplemental electric strip heat lockout until the outdoor temperature is < 40°F. – Clarification was created to incentivize variable capacity HVAC units in terms of equipment sizing and selection as per ACCA Manuals J and S.

The < 5 ACH50 air tightness requirement would have meant that all new homes would require a whole‐house mechanical ventilation system as per the 2012 and later versions of the International Residential Code (IRC). Ventilation strategies range from simple exhaust-only and sensor-based supply-only to ventilating dehumidifiers and balanced ERV’s (energy recovery ventilators). The IRC provides a table specifying the minimum ventilation to be provided. Note that Georgia subsequently modified the 2015 IRC to not require whole-house ventilation except for homes < 3 ACH50.

For hot water lines, R-3 pipe insulation is prescriptively required for all hot water plumbing outside the thermal envelope, for any lines 3/4″ and greater, and for any buried piping. Unless a simulation-based tradeoff is used, hot water lines must meet the insulation requirements of section R403.5.3. Hot water recirculating systems must be pumped and require insulated lines if controlled by a timer or thermostat. (Demand control recirculation systems are otherwise exempt from insulation.)

New Compliance Pathway

For home designs that do not meet the prescriptive code, alternate compliance options include simple UA trade-off (e.g., REScheck) and “Section R405: Simulated Performance Alternative.”

Also, the 2015 IECC introduces a new compliance pathway: the Energy Rating Index (ERI). This pathway is modeled on the Home Energy Rating System (HERS) industry and allows a simulation that looks at all energy used in the home. This is significant because this compliance pathway gives credit for more efficient mechanical equipment, increased lighting efficiency, better appliances, and renewable energy.

Importantly, regardless of which trade-off pathway is chosen, no insulation/envelope component may be installed that does not meet the minimum “backstop” requirements of Table R402.1.6, “Minimum Insulation R-values For Envelope Components When Trade-Offs Are Used.”

Information received from:

SOUTHFACE INSTITUTE ENERGY CODE HOTLINE

[email protected]